Who We Are

Leaders in the Industry

Established in 1962, first known as Normac, and later revamping to Gorf Manufacturing & Contracting Ltd. in 1968, Gorf has been providing services in the mining, lumber, construction, steel and power generation industries throughout Northern Ontario. Based in Porcupine, Ontario, Gorf is equipped with a 36,000 square foot building, housing a machine shop, welding, fabrication metal shop, and steel blasting & paint shop.

With 55 years of experience in the business, Gorf is proud to have put a stamp on some of the communities most well-known structures such as; Spruce Hill Lodge, Carlo Cattarello Arena (The Barn), Timmins District Hospital, St. Alphonses Church, Porcupine Ski Runners, and many more.

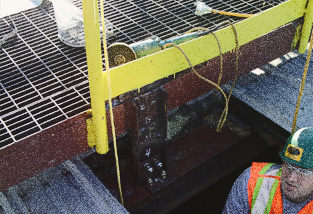

The safety of our employees/ subcontractors/ suppliers and visitors is the upmost importance. We strive to make our worksites safe for all so that everyone goes home at the end of the shift the same way they arrived. We promote good quality service with safety and security. See company safety stats and awards for more information.

As a 3rd generation company, Gorf knows the value of family, hard work, determination and success. As we continue to grow as an organization, we are dedicated to accommodate our clients needs and requirements.

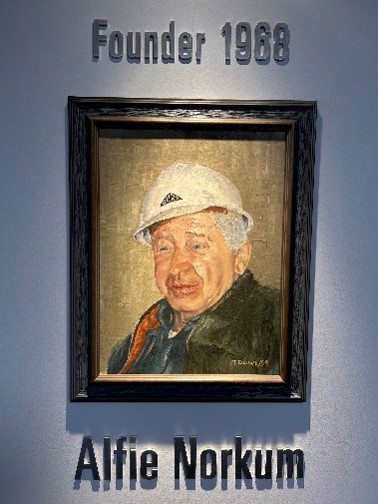

Founder of Gorf

Alphonse “Alfie” Norkum was the first-generation business entrepreneur and founder of Gorf Manufacturing & Contracting Ltd. in 1968. Father to 9 children, grandfather to many Alfie spent countless hours maintaining a well earned living to provide for his family. His career spanned over 50 years in multiple industries including but not limited to; construction, lumber, mining, fabrication, civil and mechanical.

Alfie was a major supporter of Timmins/Porcupine and the overall community growth. He showed his support in many ways such as serving on the local hospital boards, sponsoring local athletes and athletic teams and other philanthropic community opportunities. With his passion of community growth, he and Gorf helped support some of the most well known community structures that still stand and function today.

A family man, a philanthropist and a hard working determined individual, all great traits that embodied Alfie and built Gorf. Here today, at Gorf, we are grateful that the company was built off such passions and continue to nurture the company with those foundational qualities.

Shop Facility and Capabilities

Our shop facility is 36,000 square feet housing a fully equipped machine shop, welding and metal fabrication shop, steel blasting facility, and painting facility.

The shop is equipped with 5 cranes listed below.

- OVERHEAD CRANES

- One 30 TON OVERHEAD CRANE

- One 10 TON OVERHEAD CRANE

- Two 7.5 TON OVERHEAD CRANES

- One 2 TON OVERHEAD CRANE

Sandblast Shop

A high-velocity system that uses steel grit to clean surfaces, before they go out for painting.

Paint Shop

We have a high standard when it comes to our final touch. With the last process of fabrication we make sure our commitment stands alone with the proper paint job.

Machine Shop

Our machine shop houses a number of machines ready to produce and create. Paired with our experienced team we can provide exceptional products quick and reliable.

EQUIPMENT

CNC 10 x 40 PLASMA WATER TABLE

Our plasma cutting table is capable of piercing up to 2” thick and edge cutting up to 3-1/4”. The cutting table is also capable of cutting pieces as thin as 24Ga. The table is equipped with an oxy fuel torch for cuts 3” and greater. The plasma head is 5 axis allowing us to do bevelling and countersinking. The plasma table is also equipped for plasma etching and marking. The table has a cut dimension of 10’ x 40’ and has been sectioned to allow for coping and hole cutting on structural steel.

350 TON CNC PRESS BREAK

The press break is equipped for 5 axis bending eliminating “crowning”. Thus producing long consistent and even bends. The press break is also equipped with a 6 axis back gauge giving us the capability to bend cone sections. The Delem 69T CNC system gives the operator 3D visual and simulation of the bend sequence. The press break is also equipped with a segmented top die and laser guarding for the front and back of the machine.

Other equipment

Webb Plate Roller, Sampson Pan Break, Hydmech 16-A Saw, Hydmech S20-P Saw, Haco Profile Roller, Hydraulic Ironworker, Pearson Plate Shear, 450 Ton Cincinnati Press Break

Commited to Our MISSION

Health & Safety

The safety of our employees/ subcontractors/ suppliers etc. is the upmost importance. We strive to make our worksites safe for all so that everyone goes home at the end of the shift the same way they arrived. You can trust in Gorf to get the job done in a safe and efficient manner.

Quality Control

At Gorf, we understand the importance of a quality product. We want to ensure that our customers receive their product as per their requirements safely, on time, and on budget. We don’t want our customers to experience down time due to a product not meeting their specifications, arriving late, or failing. As such we strive to supply customers with best product by following our ISO 9001 compliant quality management system. The management system ensures quality from the quotation to job award, production, and delivery.